Physical assets contain useful data for asset managers. In most cases, the data is not used to its fullest extent or at all. IoT-empowered assets allow all data to “leave” the asset and communicate it to systems or people who can make the data actionable. The insights gained from the real-time monitoring can then be used to improve and optimize the functionality and usage of diverse assets.

Furthermore, since industrial markets are exceptionally asset-intensive, implementing IoT technology to optimize their performance is key to differentiating a business and gaining a competitive advantage. Doing so will additionally lead to lower operational costs, reduced resource consumption, increased productivity, and higher asset uptime.

“Businesses with higher asset uptime are 9% more profitable.”

IoT-enabled asset performance optimization

Most industrial organizations rely on critical equipment and cannot afford unplanned downtime as that would highly disrupt operations, and thus productivity and profitability. This makes ensuring optimal asset uptime and longevity key priorities for asset managers, which requires them to have complete visibility into the status and activities of all assets, including usage schedules, performance, maintenance history, and more, at all times. Fortunately, IoT technology makes it easier than ever to achieve this level of visibility.

By integrating IoT technology into physical assets (including legacy ones), managers can continuously monitor asset performance and efficiency in real time. Automated alerts and notifications can be sent to operators and end-users when incorrect use or off-spec conditions are detected, thus enabling any stakeholder to proactively address the problem. Moreover, the data can be used to undertake predictive maintenance and to determine problem areas before they affect the asset.

“Only 18% of assets have an age-related failure pattern, 82% have a random one.”

Predictive Maintenance

Using IoT technology enables predictive maintenance in assets that require a lot of care and attention to operate at their optimal level. Instead of performing repairs reactively or doing maintenance based on a predefined schedule (including to those assets that might not need it), undertaking predictive maintenance based on data output from the IoT-enabled assets results in:

- Significant cost reductions.

- Higher operating margins.

- Less downtime.

- An extended operating life.

- The forecasting of future needs.

- And in predictable and seamless operations.

“Every journey must start with a good understanding of where you are.”

Data-driven decision making

Through the provision of data, IoT technology also enables asset managers to optimize performance by identifying opportunities for process improvement. By analyzing data on asset usage and performance, asset managers can identify inefficiencies in existing processes and implement changes that enhance performance and productivity.

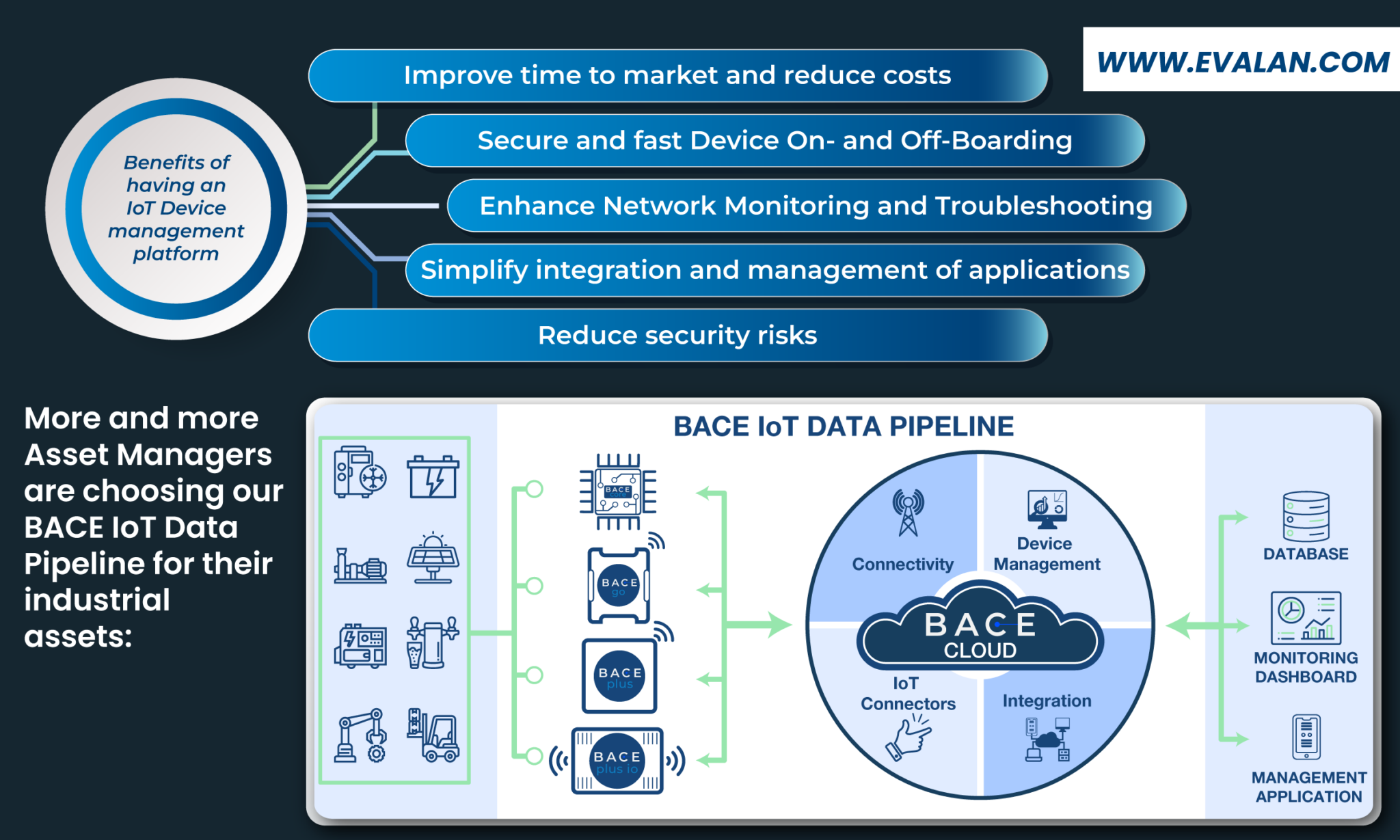

BACE: The IoT solution for asset managers

BACE Core is EVALAN’s integrable IoT gateway, which can be integrated into key assets and products quickly and easily to let asset managers achieve their goal of optimizing asset performance and enhancing their value over time, while minimizing risks and maximizing returns.

Our product BACE (Build a Connection Everywhere) can digitalize any imaginable physical asset and establish bi-directional communication via a wide range of IoT transport protocols to then integrate them to any cloud application using built-in cellular connection.

BACE is easy to integrate with your daily processes, is scalable, future-proof, and reliable, as EVALAN brings the experience of developing more than 20k connected devices.

For more information

Send us an email to info@evalan.com.

Or book a meeting here.