Project

Vitens – Leak Detection System

The project

The problem

Searching for leaks is time-consuming and major damages are expensive to repair. Moreover, leaks lead to outages. Without insights into leaks, customers cannot be informed about these outages on time. These problems led Vitens to ask EVALAN to develop and implement a leak detection system that would allow them to detect and resolve faults more quickly and save costs.

The solution

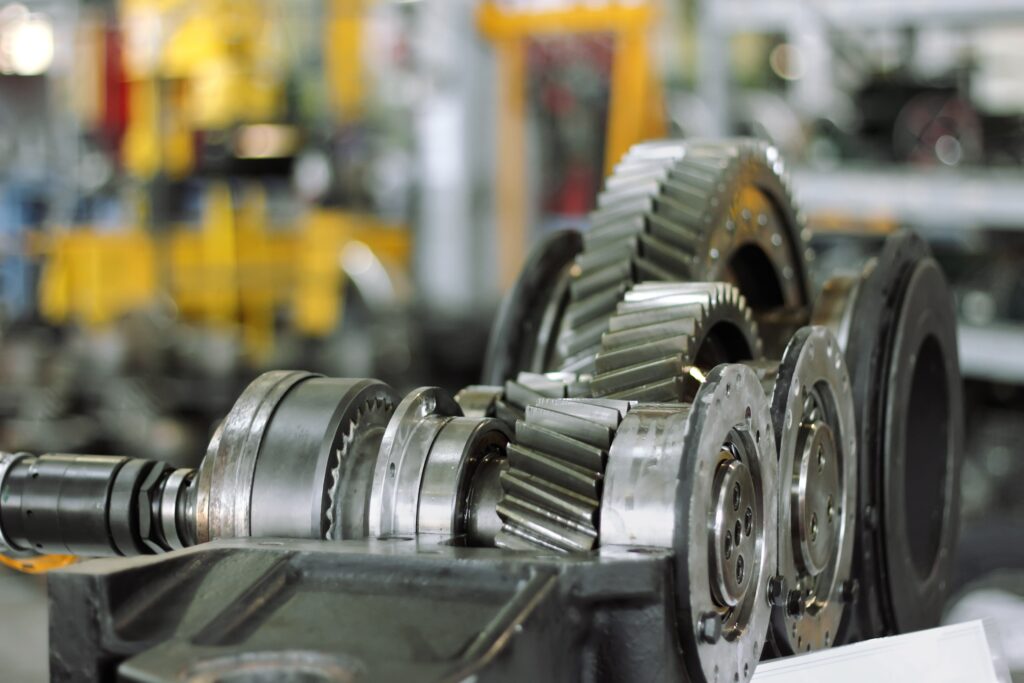

We developed an IoT solution that measures vibrations in water pipelines remotely and wirelessly. The system measures vibrations, pressure, force, and flow rate. This provides real time insights into the condition of the water pipelines. Vitens can now save costs by detecting and repairing failures faster and by predicting and preventing them. With the accelerometer we measure vibrations on the spindles of the valves of the water pipe. They recognize a normal pattern of the water flow and therefore can immediately detect deviations by means of the vibrations on these spindles. When a deviation is detected, an alarm is sent to Vitens.

The key benefits

- Accurate monitoring of waterflow and vibrations in pipelines.

- Deviations are visible at an early stage and result in immediate action.

- Preventing outages and expensive repairs caused by major damage to pipelines.

More information

Real-time measurement data

The vibration measurements provide extensive real time insight into:

- The condition of the flows through the pipelines.

- Disruptions in the flows at an early stage.

- Potential problems in pipelines.

- Deviations and their location.

All measurement data is sent wirelessly to a central platform after which the information is instantly presented on a dashboard.

More Success Cases

- What we do