Machines need to carry out their tasks efficiently and effectively. Having machines operating below the optimum can mean loss of profitability and falling behind the competitor. As such, it is crucial to ensure that key assets in the production process are continuously monitored to achieve maximal productivity and minimal downtime.

Monitoring machine performance and detecting early signs of wear can be challenging and time-consuming, particularly when dealing with a large number of machines. Commonly, this task is done:

- Manually, thus requiring a person to schedule time to go on-site and check the equipment.

- With monitoring applications that require a person to stand at near distance of the machine, as they work with short-range standards like Bluetooth.

- With applications that are machine-specific, thus leaving asset managers to juggle several vendor specific applications to keep track of all the machines.

This is where EVALAN’s IoT remote monitoring technology comes in, providing a solution that gives remote visibility in real time to all machines and equipment from a single IoT platform.

The Need

Depending on the role one plays in the industrial sector (e.g., industrial asset manager, distributor, or industrial component producer) the needs differ greatly and include, for example, being able to:

- Monitor machines and equipment remotely without having to put a person on-site.

- Use only one IoT monitoring system and dashboard to track all machines and equipment continuously and in real time.

- Predict when maintenance will be needed, minimizing costs, and reducing downtime.

- Predict usage patterns and availability of components to automate inventory management.

- Gain insight into the efficiency, durability, and performance of certain components in the machines or equipment.

EVALAN’s technology can address these needs and more, as it establishes bi-directional communication with the assets to manage them remotely.

The Technology

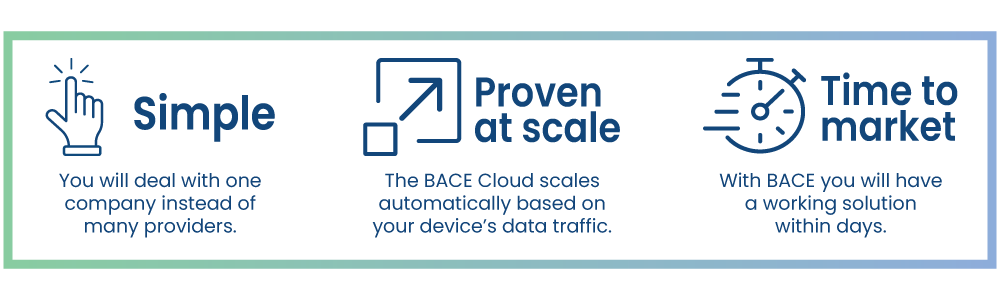

BACE (Build a Connection Everywhere) is the product line consisting of IoT gateways and cloud platform currently being used to monitor the performance of machines and industrial equipment remotely and in real time.

BACE Plus is best suited to connect to diverse industrial assets via one of the several built-in protocols and create reliable bi-directional communication between them and the cloud application. The collected information from each machine and equipment is then provided as an API (Application Programming Interface) or Webhook to any application, database, or dashboard in a neat and consistent way to cater to different stakeholders.

The Benefits

For industrial asset managers, the BACE IoT system will:

- Facilitate and increase visibility of all machines and equipment from one centralized platform.

- Reduce manhours spent in monitoring and maintenance.

- Lower costs.

- Prevent downtime and failures.

- Increase efficiency.

For distributors, the IoT system will allow them to:

- Get insights into the performance of all the products they sell to several industrial facilities.

- Provide a better customer experience by anticipating their customer’s needs.

- Provide proactive replenishing services to all the industrial facilities.

- Minimize disruptions and shorten reaction times when issues arise.

For producers, BACE will:

- Provide the insight needed to create the next and improved generation of products.

- Provide knowledge about product use, performance, and durability to better meet actual demand.

- Provide insight into an improved marketing strategy.

For more information

Send an email to info@evalan.com.

Or book a meeting with our sales managers here