SCADA —Supervisory Control and Data Acquisition— is the most widely recognized control system in industrial settings. SCADA is a software application that sits on top of the control layer of a factory’s control system enabling users to visualize and monitor the plant processes in real time. It is the user-friendly interface that operators see and with which they interact to supervise and control industrial processes.

While SCADA is a widely recognized and effective technology, it has some limitations, and its high cost makes it unaffordable for many businesses in the industrial sector. That is where the Industrial Internet of Things (IIoT) comes in, particularly in the following three cases that will be discussed in the second part of this article:

- As a cost-effective alternative to SCADA for smaller facilities that cannot afford the system.

- As an extension of the SCADA system to fill in the gaps and include, for example, old machines that were never included in the SCADA system and other simple systems like bearings or lubrication.

- As an enhancement to the SCADA system which adds an advanced layer of data processing and data collection.

Understanding SCADA

Layers of a control system in a factory

SCADA is not a complete control system in and of itself. Instead, it is one of the several layers that make up the typical control system found in a factory. These layers include:

- Sensor layer. Which consists of sensors and actuators that gather data from machines and equipment and transmits it to the network layer.

- Network layer. Which connects the sensor layer to the computing and data processing infrastructure.

- Control layer. Which uses PLCs (Programmable Logic Controllers) or RTUs (Remote Terminal Units) that process the data received, make decisions based on it and communicate with equipment.

- SCADA (or Supervisory) layer. Which collects and analyzes the data from the sensors and controllers to display it in a user-friendly interface for the operators to be able to monitor and control operations.

- And Enterprise layer. Which integrates business processes of the organization and is responsible for all the management including resource planning.

In that sense, SCADA makes use of the data gathered by devices in other control system layers to provide supervisors with real-time insights into the factory’s processes, allowing them to make informed decisions and take appropriate actions to optimize performance.

Strengths and limitations of SCADA

From the beginning, SCADA systems made the management of industrial processes a lot easier, which is why the factories that could afford it implemented SCADA to:

- Gather data in real time, improve decision-making and supervise several operations simultaneously.

- Automate routine tasks that were once performed by technicians.

- Control industrial processes and machines that would be too complex to control manually.

- Detect abnormalities on time, receive alarms and respond automatically with a programmed function.

- Display data in multiple formats.

As good as SCADA systems work for factory monitoring, they are still expensive and have limitations in:

- Scalability.

- Integration with diverse assets and devices from different manufacturers.

- Interoperability with several devices that speak different protocols.

- Advanced analytics capabilities that can harness an increasing array of data sets.

- Sharing data in different formats catering to diverse stakeholders.

In that sense, even if you have a working SCADA system it is worth looking into technology like IIoT to enhance and expand it.

And, for those who are unable to afford a SCADA system but still wish to remotely monitor, control, and automate their industrial processes continuously and in real time, IIoT is the answer.

IIoT (Industrial Internet of Things)

This section will address the three use cases for IIoT mentioned at the beginning of this article, namely: as an enhancement to SCADA; as an extension to SCADA; and, as an alternative to SCADA.

IIoT as an enhancement to SCADA

Seen as a concept, the Internet of Things (IoT) is where Operations Technology (OT) meets Information Technology (IT). SCADA is a system from the OT world, which is why matching it to the IT world opens the door to many more benefits.

Using the functions that IoT has available in cloud and software adds a different layer of data processing and data collection capabilities for the industry. In addition to enabling advance processing and analytics with Machine Learning and Artificial Intelligence, other benefits include for example:

- Overcoming scalability issues, both for increasing data sets and number of users.

- Overcoming vendor lock-in and enhancing integration.

- Extending the interoperability of platforms taking advantage of open standards.

- Retaining and storing data long term for in-depth analysis.

- Extending remote control across different networks and architecture.

- Strengthening machine-to-machine communication.

- Enhancing data accessibility and operability from a greater distance.

IIoT as an extension to SCADA

In every factory setting, there is equipment (e.g., auxiliary equipment) and small systems (e.g., bearings and lubrication) that are crucial for efficient operations but remain unmonitored by the SCADA system. This could be attributed to many factors such as:

- Budget constraints.

- Outdated or simple machinery lacking advanced controls and modern technology.

- Physical distance from the central control system.

In such cases IIoT technology is a cost-effective solution to extend SCADA systems to have a complete connected ecosystem, as the technology will help to fill in the empty spots in the visibility, control, and monitoring map.

IIoT as an alternative to SCADA

IIoT offers a cost-effective solution for smaller companies that find SCADA systems financially unfeasible, as it can fulfill the same functions of a SCADA system while being affordable.

By implementing IIoT through sensors, gateways, cloud computing and creating a leaner logic than the one SCADA uses, smaller factories will have a control system that will allow them to remotely monitor and control all their processes through one IIoT platform in a simpler and effective way.

With the right IoT partner, IIoT connected systems are easier and faster to implement than SCADA systems. They are also easier to customize and maintain and allow for better integration to already existing systems in the plant.

BACE IoT

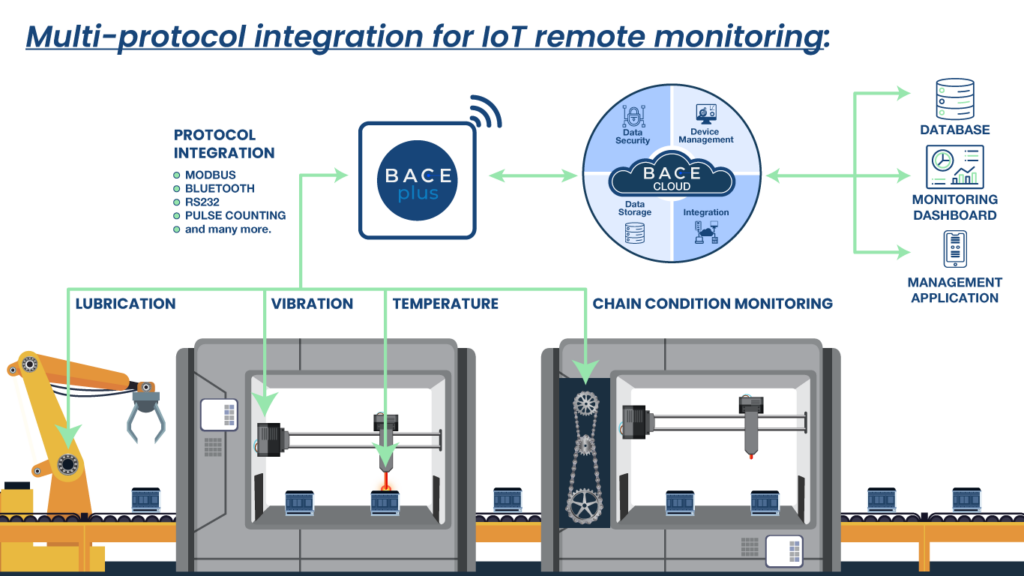

EVALAN’s BACE is the IoT solution being used by the industrial sector to monitor factory processes, machine performance, and equipment status remotely and in real time. The solution consists of two highly integrated parts: the gateway and the cloud platform.

The gateway is a multi-purpose IoT module that can be used to collect data from almost every system, machine, and asset in a factory. The BACE gateway connects to the devices in the field via one of its several built-in protocols including CAN bus, Modbus, Z-Wave, and sends it securely to the cloud platform making the data instantly usable and visible in any application, database, or dashboard. It is also possible to access the data from authorized third-party platforms, via a RESTful API.

For companies looking for a cost-effective supervisory and controlling system for their factory, BACE IoT is delivered with a dashboard that:

- Is optimized for the monitoring of devices and the visualization of their performance.

- Presents analytics and data-driven insights in an easy and understandable way.

Furthermore, the dashboard can be:

- Customized to match the specific needs of each operation.

- Expanded from a foundation that can be used to monitor the parameters of each connected device.

- Programed to generate alerts during out-of-spec conditions.

More information

Send us an email to info@evalan.com.

Or book a meeting with one of our sales managers here.