Project

Heineken – New Beer System

The project

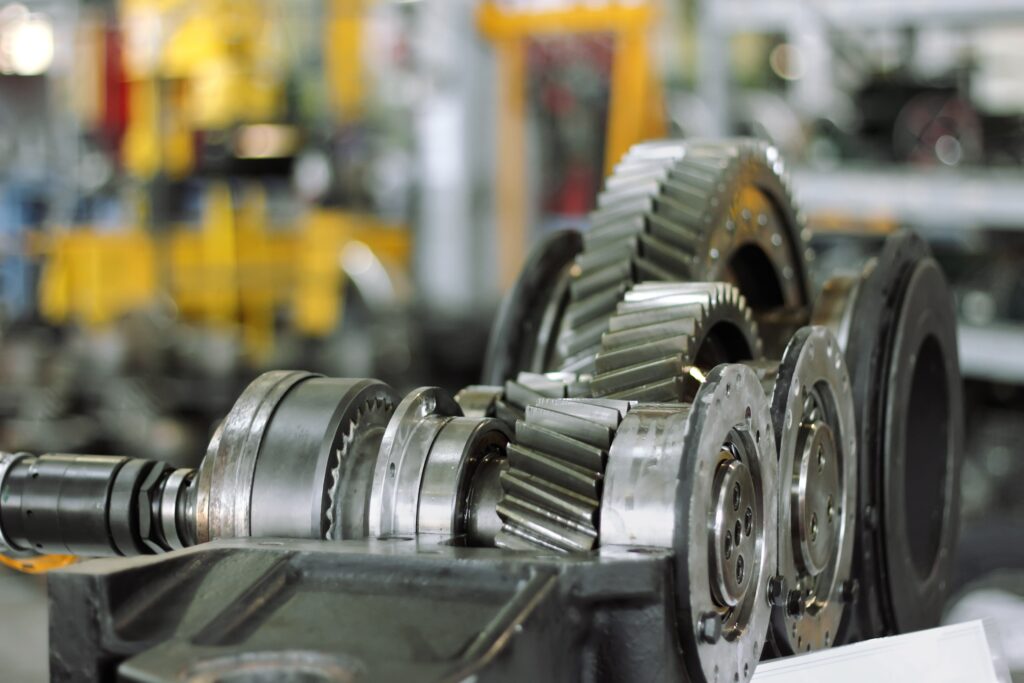

The problem

Implementing IoT can be a complicated process. Challenges include connectivity, power, security, and integration. The IoT system that Heineken had was underperforming and did not meet their expectations. We helped redesign their IoT system to make it stable, reliable, future-proof and operationally manageable.

The solution

The system we (re)developed for Heineken consists of sensors. They measure the beer volume, temperature, and other quality parameters, which are sent to our user-friendly interface. All measured data is instantly available in the new and secure web portal.

We replaced the user interface with a user-friendly web portal and implemented software changes to increase reliability. The data displayed on the web portal is now up-to-date, reliable and shows each user the data of interest. This allows for immediate action if the beer is running low somewhere or the temperature deviates.

The key benefits

- Quality is now accurately monitored, and any deviations are immediately detected.

- Deliveries to outlets are more efficiently and accurately planned.

- Cost saving in logistics.

More information

Software improvements

We have significantly improved the software of the remote monitoring system. These improvements ensure that Heineken receives reliable data. With this information, they can monitor quality accurately and plan the delivery of beer to outlets in a more efficient way. Furthermore, due to its user-friendliness, the web portal is also used a lot more by the employees.

More Success Cases

- What we do