Lock gates are an important element of the waterways in the Netherlands. Many of these locks date from the 1950’s and 1960’s, and result of the rebuilding that took place in the aftermath of the second World War.

These are now in need of upgrading or replacement. Rijkswaterstaat, a department of the Ministry of Infrastructure and Water Management, has initiated multiple improvement projects, but while these works are progressing, the older lock gates need to stay in operation.

This creates a big challenge: providing timely maintenance in order to prevent unnecessary downtime, ensure reliable operation and reduce work on site.

This is a monumental task, as there are more than 2000 locks in operation in the Netherlands and many of the waterways have multiple locks. The introduction of predictive maintenance in the operation of these lock gates supports these objectives, as it reduces the number of scheduled and unscheduled outages.

The Need

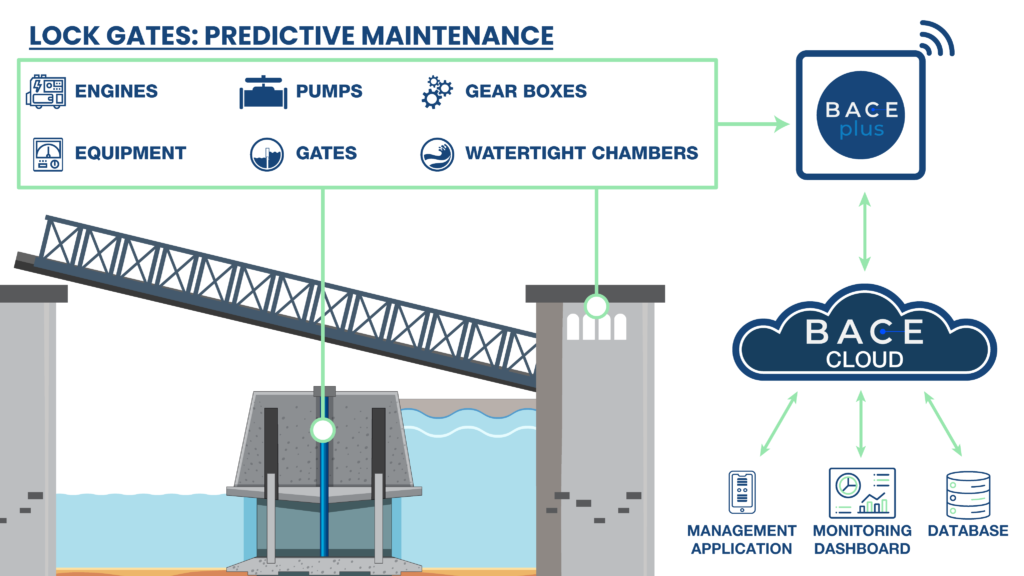

Introducing predictive maintenance programs that manage the maintenance planning of lock gates, for those locks that have not yet been upgraded or replaced, could provide relief. This can start by collecting sensor data from all critical equipment at the lock, including:

- Engines

- Gates

- Watertight chambers

- Gear boxes

- Pumps

- Equipment

Measurement data from parameters like temperature, vibration, humidity and flow rate contain information that can be used to predict when failures will occur, as do measurements of the time it takes for certain activities to complete – such as the opening or closing of a gate. Information about the time and nature of human actions can also contribute to the accuracy of the algorithms that are used in the predictive maintenance programs.

The Technology

BACE (Build A Connection Everywhere) is the technology that can be used for collecting data from the lock gates.

BACE Plus is best suited to connect your assets. This BACE module connects straight to your device via one of the several built-in protocols (like Modbus, CAN bus and a Pulse Counter), or wirelessly with Wifi Direct. It delivers LTE-M and 2G connectivity.

With BACE Plus, you can measure and monitor, among others:

- Temperature

- Humidity

- The number of movements

- Air pressure

- Corrosion

- Vibration

- Water level

And all other parameters that affect the performance of a lock gate.

The benefits

The benefits of predictive maintenance can be summarized in three big achievements: lower costs and fewer outages, at fewer manhours.

Collecting data from the equipment will help to:

- Gain insight in the use of the lock

- Reduce cost

- Reduce failures in vital assets

- Save energy

- Reduce investments

- Extend the lifetime of critical assets

- Prevent downtime

- Increase sustainability

- Increase operational reliability

- Reduce manhours

“Predictive Maintenance can save costs and preserve the historical Dutch infrastructure.”

The BACE gateways can digitalize any hardware imaginable and create reliable bi-directional communication between the devices in the field and the cloud application. It consists of two completely integrated parts: the BACE gateway and the BACE cloud. It is:

For more information

Send us an email to info@evalan.com.

Or book a meeting with us here: